Metrics

Midwest Precision LLC; a precision machining and assembly contract manufacturer is improving the competitiveness of its business operations by implementing Lean Manufacturing tools. A 6S program began the process. The elements of 6S are Sort, Straighten, Shine, Standardize, Sustain, and Safety. "Implementing 6S in the shop and offices has led to increased efficiencies and reduced costs" states Paul Ruley, Midwest Precision's Vice President of Engineering and Operations." The posted metrics provide visual reinforcement and are reviewed in the company's Quality Management System management reviews.

Visual Management

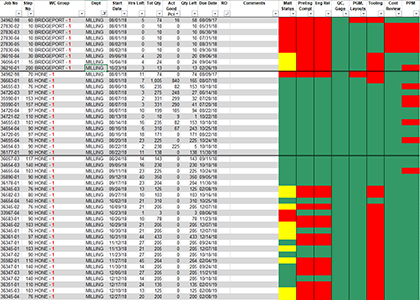

Visual Management is a useful component of the lean toolkit that highlights work queues and increases visibility of bottlenecks to company personnel. Other examples of visual management being used include production cycle metrics, outside process queue tracking and product traceability cards.

Information Technology

Midwest Precision is using Information Technology on the plant floor to supplement its lean initiatives. Two examples currently in use are paperless labor reporting and electronic scheduling displays. For labor reporting, bar coded job routers are scanned by employees when reporting production which reduces errors and provides production information immediately to management. Electronic scheduling displays reduce queue time and eliminate waste by highlighting job readiness through a "red / green" matrix. An "all green" matrix signals to setup personnel that all elements of a job are in place (e.g. material, gaging, tools & fixtures, etc.) prior to beginning a setup.

Midwest Precision Improves Competitiveness through Implementation of Lean Manufacturing Methods

- 6S Program Increases Efficiencies & Reduces Costs

- Visual Management Empowers Employees to Eliminate Bottlenecks in their areas

- Shop Floor Information Technology Streamlines Communications and Reduces Cycle Times